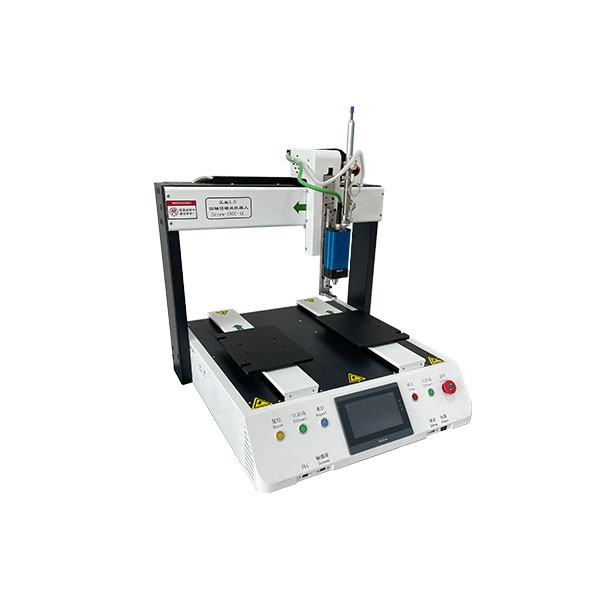

Automatic Screw Machine

Short Description:

It is suitable for most screws with strong versatility [Tel: 13652304215]; can realize mechanized production; reduce the labor intensity of workers; traditional manual screw placement and alignment of the screw head require a lot of working time and energy

Automatic Screw Machine

The automatic screw machine is an efficient and precise mechanical equipment specially designed to automate the thread assembly process. The machine adopts advanced control system and precision transmission device, which can quickly and accurately install screws of various specifications. With its many advanced features, automatic screw machines differ from traditional screw installation methods. It has functions such as automatic feeding, automatic identification of screw specifications, automatic tightening, and automatic determination of screw quality. The machine is equipped with high-sensitivity sensors that automatically detect the length, diameter and material of screws, ensuring optimal screw quality and fit. No more worrying about inappropriate or substandard screws compromising the integrity of your product.

One of the outstanding features of the automatic screw machine is its intelligent control system. The system can be flexibly adjusted and set up according to production needs. The machine is simple and convenient to operate, and the human-machine interface provides clear and intuitive guidance. By using automatic screw machines, a single operator can effectively monitor the operation of multiple machines, significantly improving production efficiency.

Automatic screw machines are not only suitable for large production lines, but also suitable for small workshops. Gone are the days of laboriously manually installing screws and aligning screw heads. With automatic screw machines, these time-consuming and labor-intensive tasks can now be automated seamlessly. This machine is compatible with most screws, realizing mechanized production and greatly reducing the labor intensity of workers. It has high reliability and stability and can achieve continuous high-speed operation, thereby reducing manual intervention and improving work efficiency and quality. The machine simplifies the installation process, saving valuable time and effort, ultimately improving overall production efficiency and quality.

With its powerful functions and unparalleled precision, automatic screw machines have quickly become indispensable and important equipment in modern production lines. Its impact on efficiency, productivity and product quality is undeniable. By adopting this cutting-edge technology, manufacturers can stay ahead of the curve and meet the growing demands of the market. Automatic screw machines are a smart investment for any industry, including electronics, automotive and machine manufacturing.

the automatic screw machine is an innovative and efficient piece of machinery that revolutionizes the screw installation process. Its advanced features, intelligent control system and compatibility with various industries make it the preferred solution for automated thread assembly on production lines. Increased productivity, improved product quality and reduced labor costs are just a few of the many advantages this machine offers.

| Model number | ACA-530LS |

| Material | aluminum alloy |

| Operating speed | 500 mm/s |

| Travel | 400 * 370 * 70 mm (customized according to customer requirements) |

| Alarm items | sliding teeth, leakage lock, poor floating |

| Operating area | protective type |

| Operation interface | Touch screen / handle |

| Collecting method | vacuum suction / magnet adsorption |

| Operating voltage is AC220V / 50-60 HZ / 1. [] 5KW |